Have you ever imagined powering your city with your daily walks? Pavegen’s innovative floor tiles make this a reality!

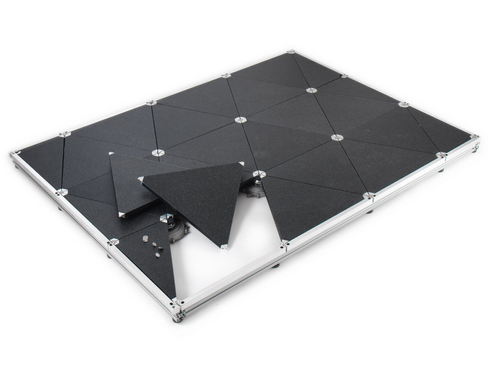

Founded on 2009, The pavegen tiles are special floor tiles that generate electricity from footsteps. Each footstep on a Pavegen tile can generate up to 7 watts of energy. This energy is typically stored in batteries or used to power nearby devices, such as LED lights or sensors. As you walk on them, the pressure triggers a tiny internal generator, converting your step into usable energy.

How these tiles can change the future of power generation?

- Aiding to the power consumption of crowded public places –

Each tile by Pavegen can generate up to 7 watts of power on each footstep. A 100-square-foot area on a busy subway can generate up to 3,780 kW of energy per day, enough to power all the lights in the station.

2. The modular nature makes deployment of these tiles easier than normal pavement –

The modular nature of Pavegen’s energy-generating floor tiles makes their deployment easier than normal pavement. Each tile can be quickly installed or replaced without extensive construction, minimizing disruption. This modularity allows for scalable installations, where tiles can be added or relocated as needed.

3. Wide variety of applications –

Pavegen’s energy-generating floor tiles have a wide variety of applications as they can be installed in commercial spaces like shopping malls and retail stores, transportation hubs such as airports and train stations, and sports and entertainment venues etc.

Patents behind this Energy-Generating Tiles Innovation

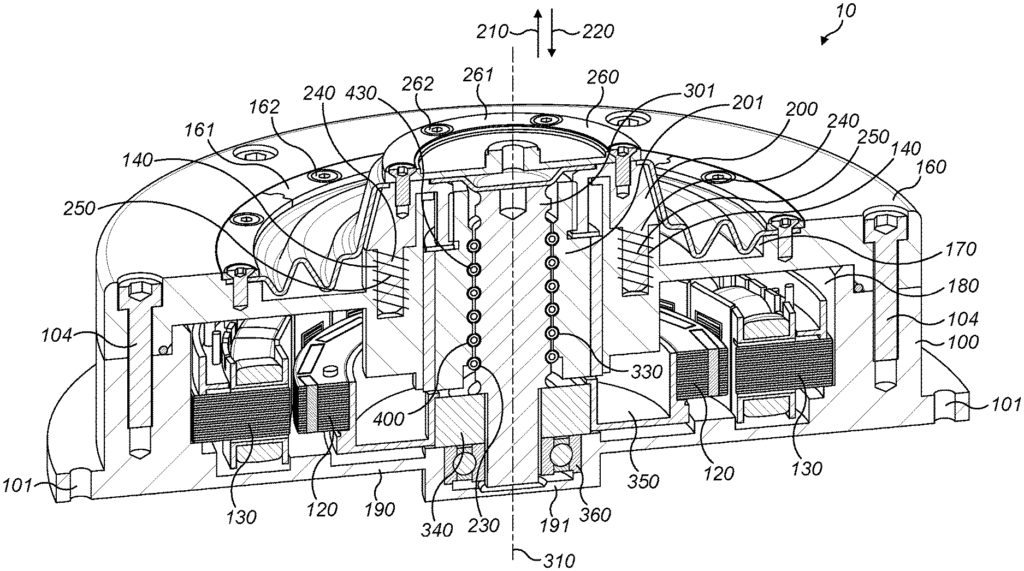

The patent US11309769B2 describes a generator that converts small movements, such as footsteps, into electricity. It includes a housing, a rotor, and an actuator that transforms linear motion into rotation. Coils on the rotor and stator generate electricity, which is then converted to DC by a rectifier. This harvested energy can power low-power devices like sensors or LEDs.

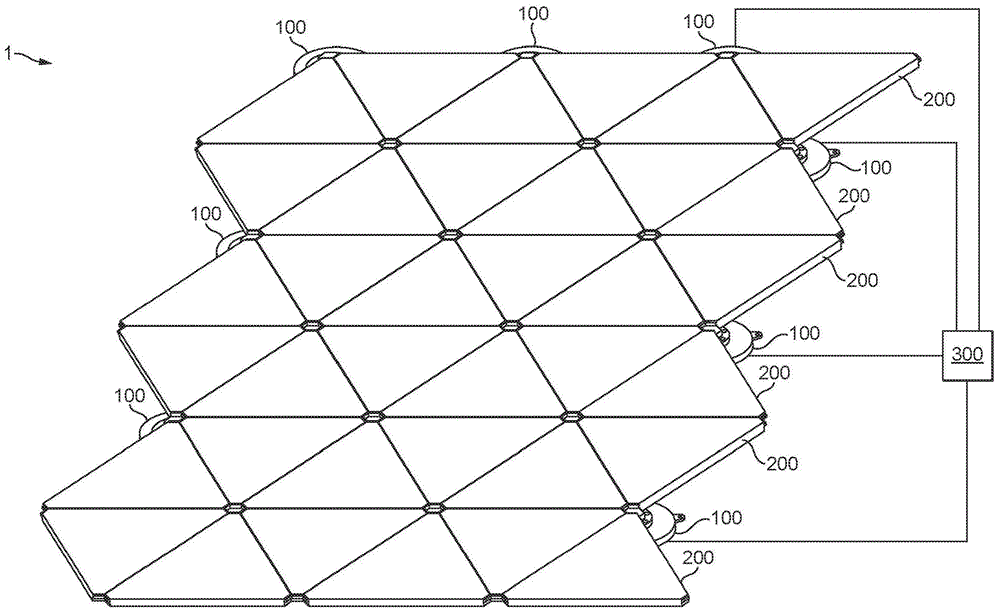

The patent CN108474360B describes a floor system that generates electricity from footsteps and allows tracking of pedestrian movements. The system uses tiles with integrated force sensors and electromagnetic transmitters. When a person steps on a tile, the force sensor activates the transmitter. Mobile devices pick up the signals and send them along with motion data to confirm steps. This allows monitoring footfalls without trip hazards from movable tiles. The system also characterizes step locations, directions, and identities using multiple sensors per tile.

The patent US8736088B2 describes a kinetic energy harvesting system for converting motion into electricity. The system has a motion converter with moving engagement elements that engage and disengage a rotatable disk. Footsteps or vehicle weight pushes the engagement elements toward the disk. This causes progressive engagement to spin the disk. As weight is removed, the elements disengage allowing free spinning. The spinning disk drives an electric generator. The harvested kinetic energy is converted to rotational energy. The system can be installed as flooring to capture footstep motion.

The patent CN108431410B describes a flooring system that generates electricity from footsteps while avoiding trip hazards and providing additional functionality like step analysis, user tracking, and occupancy monitoring. The system uses adjustable height/orientation generators instead of independent tiles to eliminate trip hazards. It also has fixed sensors, receivers, and transmitters to characterize steps, monitor users, and identify occupancy. The fixed components allow more efficient processing compared to independent tiles that move relative to each other. The system can also use mobile device signals for additional functionality.

The patent GB2558516A describes a ball screw-based electrical generator that converts intermittent impulse forces from pedestrian or vehicle movement into electricity. The generator has an axially movable actuator with a ball screw and nut. The ball screw transfers linear motion to the rotor via a ball nut. The rotor interacts with a stator to generate electricity. The ball screw reduces friction and allows efficient conversion of short impulse forces into rotational motion. The balls return between grooves in the screw and nut to further reduce friction.