Imagine a pair of shoes made just for you—not mass-produced, but crafted precisely to match the unique contours of your feet. Now, imagine those shoes being sustainable, fully recyclable, and created in a single seamless piece through cutting-edge 3D printing technology. That vision is a reality, thanks to Zellerfeld, a company that’s rewriting the rules of footwear design and manufacturing.

With a bold mission to disrupt traditional shoemaking, Zellerfeld has introduced a new era where innovation meets sustainability. Recognized as a pioneer in additive manufacturing, the company has been making headlines for its ability to deliver custom-fitted and eco-friendly footwear that doesn’t just fit better but is better for the planet.

Their latest buzzworthy creation? A collaboration with Nike on the Air Max 1000—an almost entirely 3D-printed sneaker that combines iconic design with futuristic production methods. This isn’t just a shoe; it’s a statement about the power of technology to reshape industries.

What are the innovative features of Zellerfeld’s Footwear?

- Customized Fit: By employing TextureMap technology for foot scanning, Zellerfeld ensures each shoe is tailored to the individual’s foot shape, enhancing comfort and support.

- Sustainable Manufacturing: The 3D printing process minimizes material waste and energy consumption, aligning with eco-friendly production practices.

- Recyclable Materials: Zellerfeld’s shoes are fully recyclable, allowing worn pairs to be broken down and remade, contributing to a circular economy.

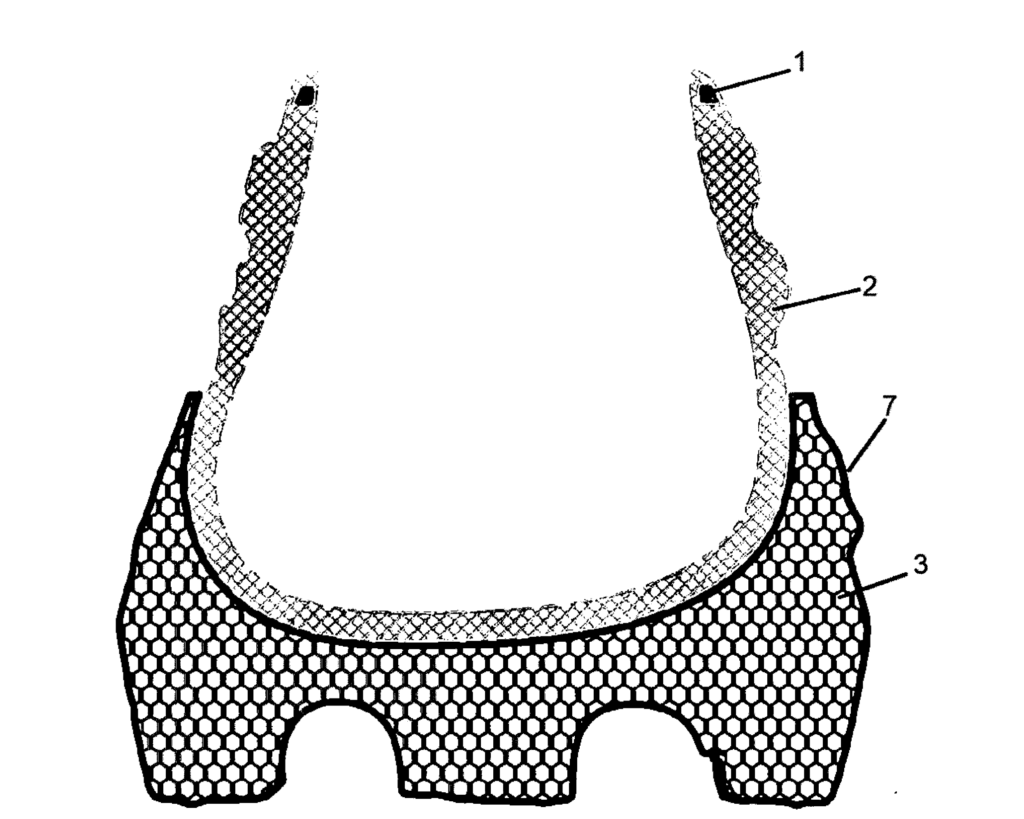

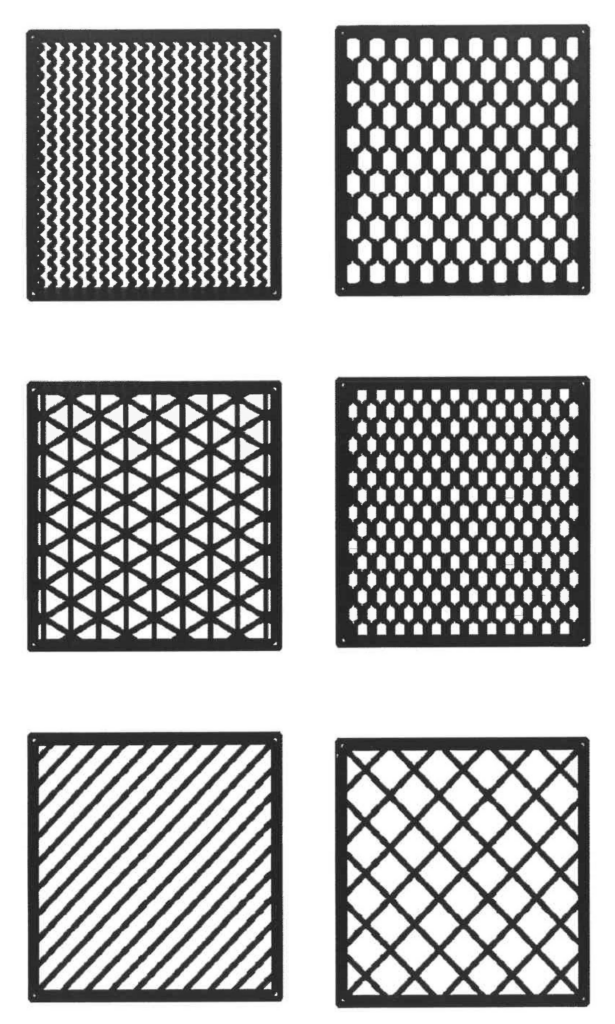

The German patent DE102020134848A1, filed by Zellerfeld, details a shoe comprising an upper part and a sole, both manufactured as a single piece using 3D printing with thermoplastic materials. This method allows for varying structures in the upper and sole, optimizing comfort and durability.

The patent image below shows the section in the area of the entry through a shoe produced by 3D Printing by Zellerfeld.

The patent image below shows an exemplary selection of structures in the form of six different geometries which are used for 3D Printing.

Who are the competitors in 3D-Printed Footwear?

Several companies are exploring 3D printing in footwear:

- Adidas: Introduced the Climacool24, a shoe with a 3D-printed midsole, emphasizing breathability and comfort.

- Reebok: Developed the Liquid Factory line, utilizing 3D printing for customized shoe components.

- New Balance: Launched the 990 Sport, featuring a 3D-printed sole for enhanced performance.

Zellerfeld isn’t just making shoes; it’s rewriting the rules of an entire industry. By blending technology, sustainability, and personalization, they’ve created a product that stands out not just for how it’s made but for what it represents—a shift toward smarter, greener manufacturing. With every pair, Zellerfeld proves that innovation isn’t just about what we wear but how we imagine the future. As they continue to push boundaries, one thing is clear: this is more than a step forward—it’s a leap into a new era of footwear.