The Rise of Carbon-Plated Running Shoes: Technology, Performance & Industry Momentum

Carbon-plated running shoes have quickly evolved from niche prototypes to one of the most disruptive innovations in modern athletic footwear. By embedding a rigid carbon fiber plate inside highly responsive midsoles, these shoes enhance forward propulsion, reduce energy loss, and improve running economy—making them a preferred choice for both elite athletes and competitive amateurs. Their rise has been driven by record-breaking performances, rapid adoption across major brands, and strong visibility through social platforms, athlete endorsements, and sports technology communities.

Today, carbon-plated shoes dominate racing events and drive significant R&D and IP activity in the global sportswear industry. The excitement around faster race times is matched by ongoing debates on cost, durability, fairness in competition, and compliance with sports regulations. As a result, these shoes now represent not just a performance upgrade but a focal point for innovation, patent development, regulatory oversight, and strategic investment across the footwear ecosystem.

Do read about some interesting highlights of the Nike Smart Shoes, Nike Patent Portfolio, Adidas 3D Printed Shoes and Adidas Patent Portfolio:

Key Features of Carbon-Plated Running Shoes

Carbon Fiber Plate Integration: The central feature of these shoes is a rigid carbon fiber plate embedded inside the midsole. This plate increases stiffness in the forefoot, enhances stability, and acts as a lever to improve forward propulsion. By controlling how the midsole compresses and rebounds, it enables runners to conserve more energy with each stride, resulting in better efficiency and sustained speed over long distances.

Advanced High-Rebound “Superfoams”: Carbon shoes rely heavily on next-generation foams such as PEBA/Pebax, nitrogen-infused EVA, and lightweight TPU blends. These superfoams offer exceptional energy return and cushioning while maintaining a very low weight. Their soft yet responsive structure works in harmony with the carbon plate, giving runners both comfort and explosive bounce without compromising performance.

Rocker Geometry & Curved Midsole Design: A defining design element is the rocker-shaped midsole that creates a smooth rolling motion from heel to toe. This geometry reduces ground contact time, encourages efficient stride transitions, and maintains momentum with less muscular strain. The curved sole helps balance the rigidity of the carbon plate, creating a more natural and fluid running experience despite the shoe’s structural stiffness.

Lightweight and Minimalist Construction: To support speed and efficiency, these shoes are built using ultralight materials across the upper, midsole, and outsole. Their overall weight is significantly lower than traditional racing shoes, reducing fatigue over extended distances. This weight optimization ensures that energy is spent on forward motion rather than lifting heavier footwear, which is especially critical in marathon racing.

Integrated Energy Return System: The combination of the carbon plate, advanced foams, and rocker design creates a highly coordinated energy return system. This system absorbs impact forces and redirects them into forward propulsion, helping runners maintain pace while using less effort. The improved running economy from this integrated design is one of the key reasons carbon-plated shoes have become the preferred choice for competitive racing worldwide.

Current Challenges of Carbon-Plated Running Shoes

| Current Challenges | Why It Matters | Key Findings | Possible Solutions |

| Manufacturing Complexity | Production requires high engineering precision; small variations impact performance and safety. | Complex bonding of carbon plates with superfoams; specialized tooling needed; hard to scale consistently. | Advanced automated molding, improved QA systems, and standardized plate–foam integration processes. |

| High Production Cost | Premium materials and complex processes push retail prices high, limiting accessibility. | Carbon fiber and superfoams drive up cost; shoes retail between $200–$300+; low durability raises cost-per-use. | Material optimization, adopting hybrid composites, and streamlining production to reduce waste and cost. |

| Durability Limitations | Reduced lifespan impacts value and usability for everyday runners. | Superfoams lose responsiveness faster; optimal performance lasts only 150–250 km. | Develop more resilient foam formulations and improve outsole wear patterns; introduce training-friendly variants. |

| Regulatory Compliance (World Athletics) | Shoe design must meet competition laws; non-compliance affects brand credibility and athlete eligibility. | Restrictions on sole height, plate count, and plate configuration; strict timelines for commercial release. | Early integration of regulatory requirements in R&D cycles; collaboration between legal, IP, and biomechanics teams. |

| Sustainability & Environmental Concerns | Growing global pressure on brands to reduce carbon footprint and improve recyclability. | Carbon fiber is energy-intensive; foams are difficult to recycle; increasing scrutiny from environmental bodies. | Explore bio-based foams, recyclable composites, and take-back programs for end-of-life shoe components. |

| Dense IP Landscape & Patent Restrictions | High risk of infringement; limits design freedom for new entrants; slows innovation cycles. | Dozens of patents exist on plate shapes, foam blends, rocker geometries; companies compete aggressively. | Conduct detailed FTO studies, pursue novel plate architectures, and invest in cross-industry material innovation. |

Check out Carbon-Plated Shoes patents filed in 2025:

Innovation Behind Carbon-Plated Shoes

| Patent | Title | Company | What Problem Are Solving Through This Innovation |

| US20250288054A1 | Article of Footwear with Extended Plate for Toe-Off | Nike | Improves propulsion during the toe-off phase by extending plate coverage, enabling smoother transition and more efficient energy transfer for long-distance running. |

| CN221616372U | Bending-Resistant PMI Composite Carbon Fiber Board | Haobo Fujian New Material Technology Co. Ltd. | Enhances stiffness and structural durability of carbon plates, preventing bending or deformation while maintaining lightweight performance. |

| CN118991086B | High Elastic Modulus Carbon Fiber Plate and Preparation Process | Fujian Xingxianyi New Materials Technology | Provides a stronger, higher-modulus carbon plate that increases responsiveness and energy return, while optimizing manufacturing for consistency and quality. |

| WO2023227002A1 | Carbon Plate for Running Shoes and Manufacturing Method | Xtep China Ltd | Focuses on improving plate shape precision and manufacturing reliability, enabling better integration with midsoles and more consistent performance across product batches. |

| US10758001B2 | Energy Return Footwear Plate | Nike | Enhances energy return through a uniquely shaped plate design that maximizes rebound efficiency and reduces energy loss during footstrike. |

| US12336593B2 | Article of Footwear Having a Sole Plate | Puma SE | Provides an optimized sole plate that balances rigidity and flexibility, improving both comfort and propulsion for competitive athletes. |

| US12185789B2 | Sole Structure for Article of Footwear | Nike | Improves midsole–plate interaction, optimizing cushioning, stability, and responsiveness while reducing fatigue during extended running. |

| US8978272B2 | Article of Footwear with Forefoot Plates | Nike | Addresses forefoot stability and propulsion by using specialized forefoot-only plates to enhance toe-off mechanics and directional rigidity. |

| US20080271342A1 | Structural Element for a Shoe Sole | Adidas | Strengthens the internal structure of the sole to improve durability and arch support while maintaining flexibility and lightweight performance. |

| US12349760B2 | Article of Footwear with Extended Plate for Toe-Off | Nike | Similar to earlier Nike innovations, this design further optimizes toe-off energy transfer and plate curvature for efficient propulsion and reduced fatigue. |

Explore the complete IP landscape, competitor filings, and emerging innovation clusters → Request Full Patent Landscape Report

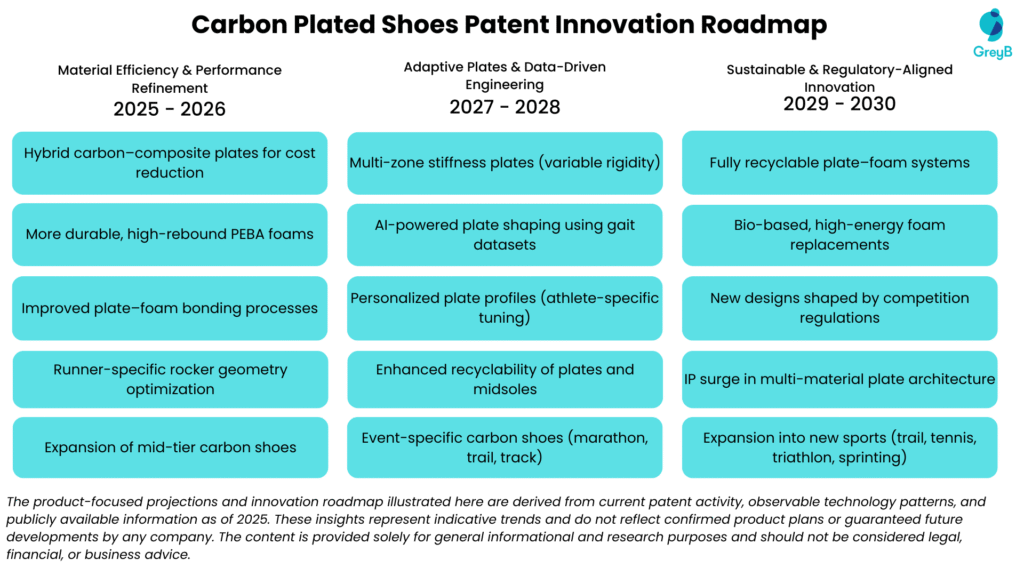

Carbon-Plated Footwear Innovation Roadmap (2025–2030)

Carbon-plated footwear is now a global innovation race led by major performance brands like Nike, Adidas, Puma, ASICS, Saucony, Xtep, and Hoka, along with emerging material innovators. Their rapid R&D investments and expanding patent portfolios highlight a highly competitive landscape where new plate designs, advanced foams, and sustainability-focused materials are reshaping the future of running shoes.

For teams tracking competitor moves, patent activity, or upcoming breakthroughs, this space offers significant opportunities for deeper analysis. If you’re exploring this market or evaluating innovation trends, our team can help you dive further.