Introduction

Rhodamine B is a xanthene-class synthetic dye historically used in textile, paper, and laboratory staining applications due to its intense pink-red fluorescence and high chromatic strength. Despite its visual potency and low cost, Rhodamine B has never been approved as a food colorant in any major regulatory jurisdiction.

Its recurrent detection in adulterated food products-particularly chili powders, sauces, confectionery, and beverages-has positioned it as a high-risk illegal additive within global food safety enforcement frameworks. The compound’s documented genotoxicity, bioaccumulation potential, and carcinogenic risk have driven explicit bans and zero-tolerance policies across food regulatory authorities, necessitating robust, compliant replacement strategies for manufacturers seeking red–pink chromatic profiles.

Why Replace This Ingredient

Rhodamine B presents multiple, non-mitigable risks in food systems. Toxicological studies have demonstrated hepatotoxicity, reproductive toxicity, and DNA intercalation activity linked to its planar aromatic structure. The dye exhibits high affinity for lipid-rich tissues and limited metabolic clearance, raising concerns over chronic exposure even at trace levels.

From a regulatory standpoint, Rhodamine B is classified as an industrial dye with no acceptable daily intake (ADI), rendering any detectable presence in food grounds for immediate product recall, import rejection, and potential criminal liability.

Replacement is therefore not a matter of reformulation optimization but of absolute compliance, risk elimination, and supply-chain integrity.

Regulatory Landscape

| Jurisdiction | Regulatory Body | Status in Food | Key Reference |

| United States | FDA | Explicitly prohibited; not listed under 21 CFR Parts 73 or 74 | FD&C Act §402 |

| European Union | EFSA / EC | Banned; not authorized under Regulation (EC) No 1333/2008 | Annex II |

| Codex Alimentarius | FAO/WHO | Not permitted; classified as non-food dye | GSFA |

| China | SAMR / CFDA | Prohibited; listed in illegal additives catalog | GB Standards |

| India | FSSAI | Explicit ban; zero tolerance | Food Safety & Standards Regulations |

Supplier Profiles: Food-Grade Colorant Alternatives

1. Chr. Hansen (Denmark)

Chr. Hansen supplies anthocyanin-based red colorants derived from black carrot, purple sweet potato, and elderberry, produced via aqueous extraction and membrane concentration. Typical purity (coloring matter) ranges from 25–40%, with pH stability between 2.5–5.0, making them suitable for beverages and acidified foods.

Thermal stability is moderate (<90°C short-time), with light sensitivity requiring opaque or UV-barrier packaging. Water-soluble systems are standard, with recommended dosages of 50–300 ppm depending on the matrix. Products are FDA-exempt color additives, EFSA-approved, and Codex-compliant, with ISO 9001, FSSC 22000, Non-GMO, Halal, and Kosher certifications.

2. GNT Group (Netherlands)

GNT’s EXBERRY® portfolio provides vegetable-derived red shades using minimally processed concentrates from radish, carrot, and beetroot. Production avoids solvent extraction, aligning with clean-label positioning. pH stability ranges from 3.0 – 7.0 depending on source, with improved heat tolerance in bakery and confectionery systems up to 180°C short-time.

These water-dispersible concentrates exhibit moderate light stability and require antioxidant systems in beverage applications. Dosage typically ranges from 0.1–1.0%. Approved globally as coloring foods, they are compliant with EFSA, FDA, FSSAI, and CFDA frameworks.

3. DDW, The Color House (USA)

DDW offers carmine and carmine-replaced blends, as well as anthocyanin–caramel hybrid systems designed to mimic synthetic red hues. Carmine (carminic acid 50–52% purity) provides excellent heat and light stability across pH 3–8, with water solubility and dosage levels as low as 10–50 ppm.

Regulatory approvals include FDA (21 CFR 73.100), EFSA (E120), and Codex, with allergen and labeling considerations. Facilities are FSSC 22000 and ISO certified, supporting beverage, dairy, and confectionery applications.

4. Sensient Technologies (USA/EU)

Sensient supplies encapsulated natural red color systems using spray-dried anthocyanins and beet pigments stabilized with maltodextrin or gum arabic carriers. These systems enhance thermal and oxidative stability in dry mixes and extruded snacks. pH stability typically spans 3.0–6.5, with improved shelf-life under low-water-activity conditions.

Dosage ranges from 0.05–0.5%. Products meet FDA exempt color additive requirements and EU coloring food classifications, supported by extensive application labs.

5. Naturex (Givaudan) (France)

Naturex produces high-purity beetroot red (betanin ≥0.3%) and hibiscus anthocyanin extracts using controlled aqueous extraction and low-temperature concentration. These pigments exhibit optimal stability at pH 4.0–6.0, with sensitivity to heat (>85°C) and light, necessitating cold-fill or HTST processing.

Water solubility is high, with dosages of 100–400 ppm. Regulatory approvals include EFSA, FDA, Codex, and FSSAI, with Organic, Non-GMO, and Vegan certifications available.

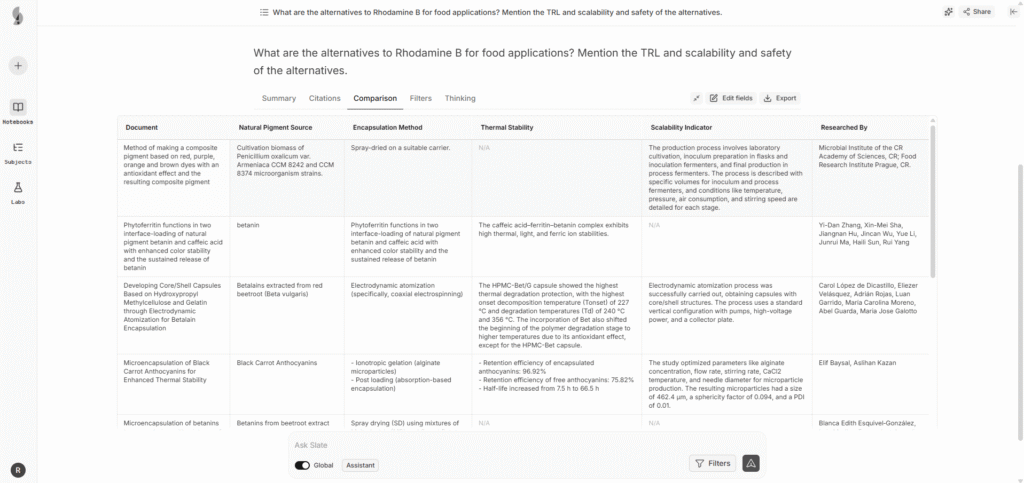

This is where an AI-powered research tool like Slate helps out. We analyzed the alternatives, their mechanism, thermal stability, scalability, and safety insights using Slate, and all it needs is a simple query, like “What are the alternatives to Rhodamine B for food applications?”

Within minutes, Slate scours through hundreds of patents and research papers, finds highly relevant inventions, and presents them in a neat dashboard. Here’s a screenshot as an example:

Access the full research on Rhodamine B alternatives here.

Segmentation of Alternatives by Scientific Domain

– Anthocyanin Chemistry

Anthocyanins provide red to magenta hues through flavylium cation structures, with color expression highly dependent on pH and co-pigmentation. Their reversible structural transformations necessitate formulation control but offer natural origin and regulatory acceptance.

– Betalain Systems

Betalains, primarily betacyanins from beetroot, deliver vibrant red shades independent of anthocyanin pathways. They exhibit higher chromatic strength at neutral pH but are thermally labile and oxidation-sensitive.

– Carminic Acid Complexes

Carminic acid functions as a metal-chelated chromophore with superior stability across processing conditions. While technically robust, its insect origin raises allergen, dietary, and ethical considerations.

– Hybrid Color Blends

Blended systems combining anthocyanins, caramel, and carotenoid fractions allow hue tuning and stability optimization, compensating for the absence of high-intensity synthetic dyes like Rhodamine B.

Research Gaps & White-Space Opportunities

- Fluorescence-Mimetic Natural Systems

No current food-grade pigments replicate the fluorescent optical intensity of Rhodamine B. Research into safe chromophore–matrix interactions could expand visual performance without regulatory compromise. - High-Temperature Stability Modeling

Predictive degradation kinetics for natural reds under UHT and extrusion conditions remain underdeveloped, limiting reliable scale-up. - Oxidative Protection Strategies

Integrated antioxidant–colorant systems require further study to mitigate color fading in high-oxygen beverage matrices. - Matrix–Pigment Binding Mechanisms

Limited understanding exists regarding protein–polyphenol interactions affecting color expression in dairy and plant-based emulsions. - Standardized Global Equivalency Metrics

There is no harmonized method to benchmark natural color strength against banned synthetic dyes, complicating regulatory and commercial substitution decisions.

Comparative Technical Table

| Active Compound | Mechanism of Action | Stability Profile | Regulatory Status | Expected Performance |

| Anthocyanins | pH-dependent chromophore | Moderate heat, low light | FDA/EFSA approved | Medium intensity |

| Betanin | Nitrogen-containing pigment | Low heat, moderate light | FDA/EFSA approved | Bright red |

| Carminic Acid | Metal-chelated dye | High heat/light | Restricted but approved | High intensity |

| Hybrid Blends | Multi-pigment synergy | Tunable | Approved components | Customized |

Formulation Considerations

Replacement of Rhodamine B requires recalibration of dosage, pH control, and processing parameters. Natural reds often demand higher inclusion rates and protective packaging to mitigate photodegradation. Interactions with ascorbic acid, metal ions, and proteins must be evaluated to prevent color loss. Labeling implications, including allergen disclosure (carmine) and “coloring food” claims, must be assessed early in development.

R&D Implementation Framework

- Audit & Risk Mapping – Identify legacy exposure risks and supplier vulnerabilities.

- Screening of Alternatives – Shortlist pigments based on matrix compatibility and regulatory scope.

- Trial Design – Conduct accelerated stability and sensory equivalence studies.

- Data Integration – Align analytical, toxicological, and regulatory datasets.

- Scale-Up – Validate processing robustness and supply continuity.

Conclusion

Rhodamine B is unequivocally incompatible with food and beverage applications under all major regulatory regimes. Effective replacement demands not only selection of compliant colorants but also deep integration of chemistry, processing, and regulatory strategy.

While natural alternatives cannot replicate Rhodamine B’s intensity directly, scientifically engineered systems provide safe, defensible pathways to achieve acceptable visual performance.

Regulatory Disclaimer

This document is for R&D informational purposes only and does not constitute regulatory or legal advice. Verify regional approvals, supplier specifications, and application performance data before commercialization.

Request the approved supplier list for food-grade red colorant alternatives. Review specifications, origin, and regulatory status.