Did you know that L’Oréal has been committed to cruelty-free product testing since 1989? Now, they’re taking that promise to the next level with bioprinted skin technology—a breakthrough that could transform the way skincare products are developed, tested and personalized.

Revealed at the Viva Technology conference in Paris in 2024, this cutting-edge innovation creates synthetic skin that mirrors the structure and function of real human skin. Whether it’s replicating specific conditions like dryness or irritation, or offering a sustainable and ethical alternative to traditional testing methods, L’Oréal’s synthetic skin is poised to reshape the cosmetics industry.

Let’s explore the groundbreaking technology, its potential applications and why this might just be the beginning of a new era in beauty.

How Does This Innovation Impact the Cosmetics Industry?

L’Oréal’s foray into artificial skin technology isn’t just a new chapter in its innovation story—it’s a redefinition of the industry. This breakthrough has the potential to:

- Redefine Product Development: With accurate testing on skin replicas, brands can innovate faster and more precisely, ensuring safer and more effective products for consumers.

- Enable Personalized Skincare: The ability to replicate specific skin conditions could lead to customized products tailored to individual needs, moving us closer to truly personalized beauty solutions.

- Elevate Industry Standards: L’Oréal’s initiative raises the bar for competitors, pushing the entire industry toward more ethical, sustainable, and innovative practices.

What Is the Technology Behind L’Oréal’s Artificial Skin?

Before jumping into the bioprinting revolution, it’s worth noting that L’Oréal’s journey with synthetic skin began over four decades ago. Since 1979, the company has been developing human skin models in laboratories to create ethical alternatives to animal testing. These models are already so advanced that they can simulate:

- Diverse Skin Types: Functional skin models that replicate dry, oily and sensitive skin conditions.

- Complex Processes: Healing, tanning and even photoaging effects.

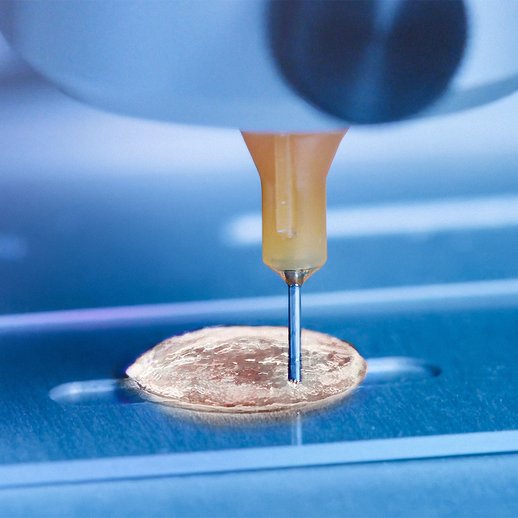

This foundation set the stage for L’Oréal’s latest breakthrough: bioprinted skin that combines precision, scalability and ethical testing in one innovation.

Key Insights from Research Article

Backed by L’Oréal Advanced Research in collaboration with the University of Oregon, this breakthrough study is a testament to L’Oréal’s leadership in skin innovation. Some of the paper’s authors are part of the Skin Tech Platform at L’Oréal Advanced Research, ensuring that the research is deeply rooted in the company’s expertise and vision for the future of skincare.

Here are the key insights from their pioneering work:

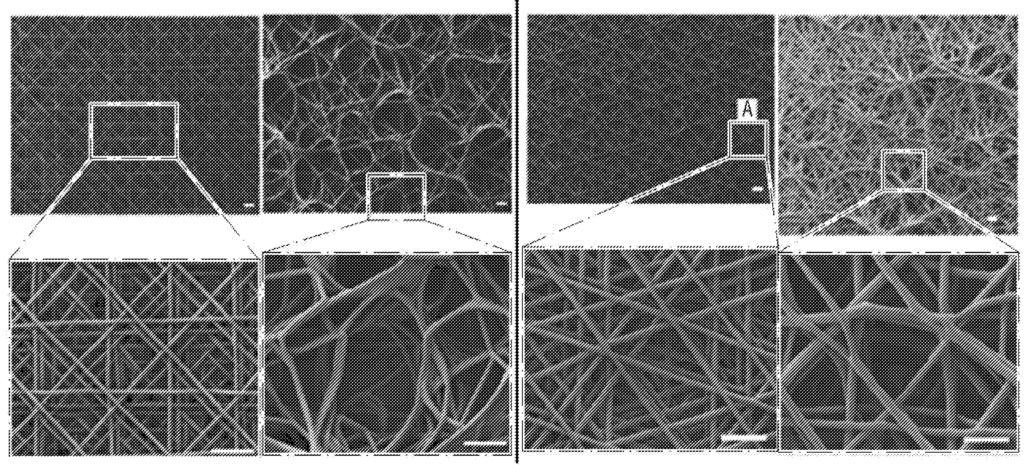

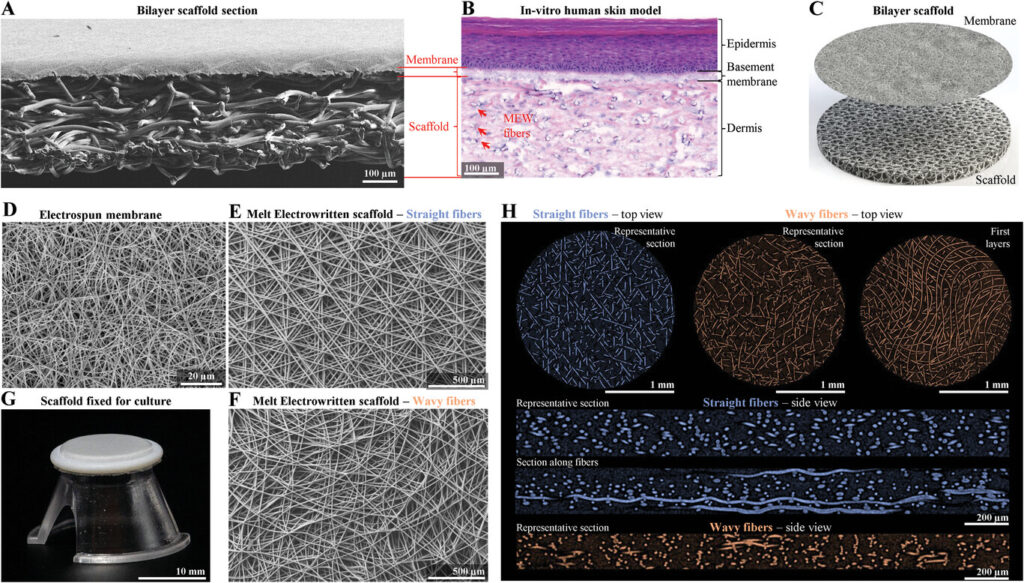

- Dual-Layer Bioprinted Skin: L’Oréal’s synthetic skin is built in two layers:

- The epidermis, made through electrospinning, mimics the skin’s protective barrier with a dense layer of pores no larger than 5 µm.

- The dermis, created with electrowriting, provides flexibility and support through a porous structure with 20 µm or larger pores.

- Unparalleled Efficiency: Traditional models require up to 35 days to grow functional skin. L’Oréal’s bioprinting technology achieves the same in just 18 days, accelerating product development cycles.

- Simulating Skin Conditions: The technology mimics specific conditions like eczema or sun damage, providing researchers with an accurate testing ground for new skincare solutions.

Key Highlights from Patent FR3127134B1

- Precision Production: The patent outlines the process for creating these bioprinted layers using advanced techniques. Each layer is engineered to mirror the mechanical and biological properties of real skin.

- Potential Applications: Beyond cosmetics, this synthetic skin has potential uses in wound healing, skin grafts and pharmaceutical testing.

- Sustainability and Scalability: Designed for mass production, this innovation aligns with L’Oréal’s commitment to sustainability and ethical practices.

Who Are L’Oréal’s Competitors in Synthetic Skin Technology?

CUTISS AG: A Swiss clinical-stage life sciences company focused on skin regenerative medicine, CUTISS has developed denovoSkin™, a personalized and automated approach to skin tissue therapy for severe skin injuries.

PolyNovo: An Australian company specializing in biodegradable polymer technology, PolyNovo has created NovoSorb® BTM, a dermal scaffold for the regeneration of the dermis lost through surgery, trauma, or burns.

Integra LifeSciences: A global medical device company, Integra has developed artificial skin used to treat severe burns and other skin wounds, becoming the first commercially reproducible skin tissue in this field.

L’Oréal’s bioprinted skin technology is not just another innovation; it’s a reimagination of what skincare can be. With products like L’Oréal Paris Youth Code and L’Oréal Paris Centella Cica Cream already benefiting from their expertise in reconstructed skin, L’Oréal is pushing the boundaries even further.

Imagine a future where your moisturizer isn’t just tested on lab-grown skin but crafted specifically for you—your skin’s needs, your unique challenges. This isn’t just about ethical and sustainable beauty; it’s about setting a new gold standard for the entire industry. As L’Oréal leads the charge, the question isn’t whether this will change skincare—it’s how soon it will transform your routine.