Adidas has unveiled its latest breakthrough in 3D printed footwear with the Adidas 4DFWD, featuring midsoles crafted using advanced Digital Light Synthesis (DLS) technology from Carbon. This innovation, highlighted by intricate lattice structures that compress forward on impact, offers superior cushioning and propulsion, enhancing comfort and performance. Worn by athletes at the Tokyo Olympics, these shoes epitomize Adidas’s commitment to innovation and sustainability, marking a new era in athletic footwear.

How Do Adidas 3D-Printed Shoes Function?

- Lattice Midsole Structure: Utilizes a complex lattice design for superior cushioning and support.

- 3D Printing Technology: Manufactured using advanced 3D printing techniques for precise customization.

- Lightweight and Breathable Upper: Made from materials that adapt to the foot for comfort and flexibility.

- Eco-Friendly Materials: Incorporates sustainable materials, including recycled ocean plastics.

- Precision and Customization: Designed to match the individual wearer’s needs for a bespoke fit.

- Enhanced Performance: Improves athletic performance through better support, flexibility and durability.

Key Patents behind Adidas 3D-printed shoes

We have analyzed key patents related to Adidas 3D-printed shoes. Read the summary below to discover the ingenious innovations behind this breakthrough technology.

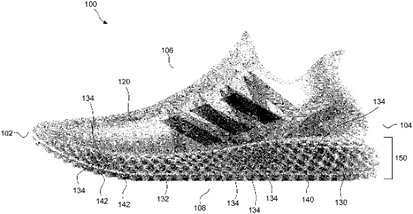

The patent, US11992084B2, introduces a mesh with anisotropic properties, offering controlled deformation for targeted support and flexibility, boosting performance and comfort. This design enhances shoe responsiveness and cushioning by optimizing forward deformation upon ground contact. With 3D printing, the mesh structure can be precisely customized, tailoring shoe performance to various athletes and activities. The image below showcases the shoe with 3D printed midsole.

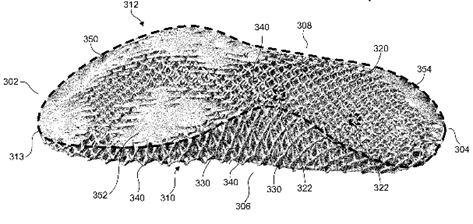

Unveiled in the patent, US20240032649A1, Adidas’ 3D printed midsole design revolutionizes pressure distribution, flexibility and stability. This customizable structure adapts to your performance needs, delivering a bespoke fit with unparalleled shock absorption, traction, and airflow. The figure below is the perspective view of a midsole.

Imagine a sole where nodes with platforms are seamlessly linked for unbeatable cushioning and support. This is introduced in the patent, EP3981277A1, where 3D mesh footwear soles crafted from a web of interconnected nodes and struts. Some models take it a step further with unconnected nodes, creating a smooth, unified base. The figure below is the bottom view of sole.

In conclusion, Adidas’ 3D-printed shoes, such as the Futurecraft 4D, are leading a significant shift in the footwear industry. While brands like Nike with their Flyprint, New Balance with the TripleCell, and Under Armour with the ArchiTech are also delving into 3D printing, Adidas stands out with its advanced Carbon Digital Light Synthesis technology. This innovation ensures unmatched precision, durability, and customizability, giving Adidas a distinctive edge in both performance and sustainability. The transformative potential of Adidas’ 3D-printed shoes lies in their fusion of advanced technology and eco-friendly materials, pointing to a future of personalized, high-performance, and sustainable footwear. As the industry evolves, Adidas isn’t just keeping up – they’re setting the pace, redefining the boundaries of design and production.

Need to know anything else? We got you covered!