Nike‘s A.I.R. (Athlete Imagined Revolution) collection is setting new benchmarks in athletic footwear with its recent launch of 3D printed shoes. Collaborating with top athletes like Kylian Mbappé, Eliud Kipchoge and Erling Haaland, Nike uses AI and advanced 3D printing technology to create shoes that are both high-performance and uniquely tailored to each athlete. This innovative approach not only enhances functionality but also brings a fresh, personalized touch to athletic footwear, setting a new standard in the industry.

What makes Nike’s 3D Printed Shoes unique?

- Custom Design: Advanced software tailors designs to individual foot shapes.

- Material Selection: Proprietary, durable and flexible materials are used.

- 3D Printing: Shoes are built layer by layer, allowing intricate designs.

- Seamless Construction: Reduces stitching and glue, resulting in lightweight shoes.

- Precision Fit: Ensures a perfect fit for enhanced comfort and reduced injury risk.

- Sustainability: Minimizes waste by using only necessary materials.

- Performance Optimization: Enhances grip, support and flexibility.

Key Patents behind Nike’s 3D Printed Shoes

We’ve analyzed key patents related to Nike 3D Printed Shoes. Read the summary below and discover the ingenious innovations behind this breakthrough technology!

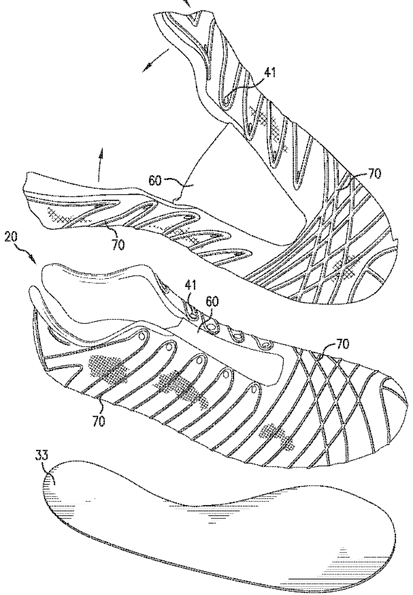

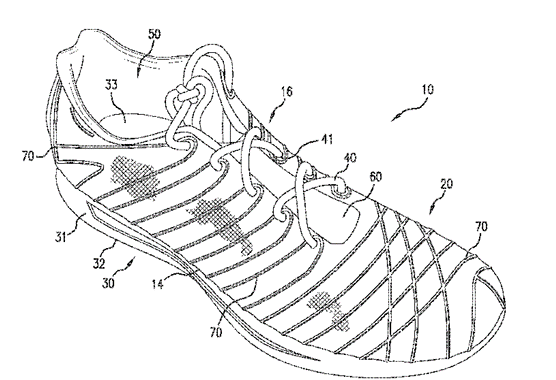

The patent US20230286209A1 introduces a revolutionary method for 3D printing directly onto apparel. This process involves placing the garment flat on a tray, printing a 3D pattern onto it, curing the material, and then removing the apparel. This innovative technique seamlessly incorporates advanced designs and functionalities into shoes, highlighting Nike’s relentless commitment to innovation and performance. Below, you can see a perspective view of the upper portion of a shoe after printing and during its assembly with the sole.

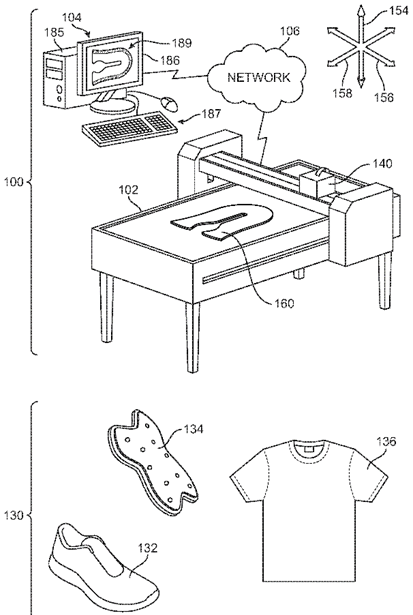

The patent, US11618206B2, details a method for printing a three-dimensional structural component onto a base, using varying thicknesses to create different layer dimensions. This innovative process allows one part of the layer to be thicker and another part thinner, enabling precise customization and optimization of the shoe’s structure. The result is enhanced comfort, performance and durability. The figure below is a schematic diagram of this advanced printing system.

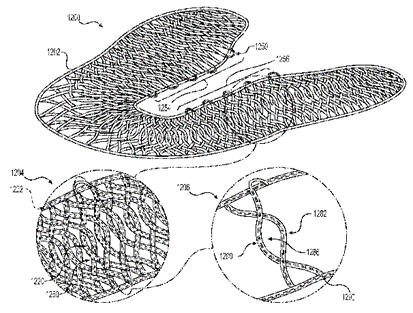

The patent, US10455896B2, introduces a ground-breaking method that prints layers of a traced element, embedding a textile strand within overlapping polymer layers. This innovative design can be integrated into the upper part of footwear, significantly enhancing its structure and functionality. The figure below illustrates a portion of this traced element in action.

Nike’s patent, US2015246496A1, reveals an innovative method for 3D printing shoes by directly printing onto fabric materials. This process involves designing a 3D pattern, placing part of the shoe on a flat tray, and printing the material directly onto it. After curing, the finished shoe is removed from the printer. This seamless integration of 3D printing technology allows for precise, customized, and sustainable shoe manufacturing. The figure below shows an elevated view of this ground-breaking footwear design.

As Nike redefines the future with its A.I.R. collection, competitors like Adidas, Puma, and Under Armour are also exploring 3D printed footwear. Adidas has made waves with mass-produced 3D printed midsoles, and Puma’s collaboration with Porsche Design showcases innovative designs. What makes Nike stand out is its seamless blend of athlete feedback and AI, crafting shoes that are not only high-performance but also uniquely personalized. This approach sets a new standard in the industry, promising to revolutionize design and manufacturing processes, and offering a glimpse into the future of custom athletic gear that excels in both function and personal style.

Need to know anything else? We got you covered!