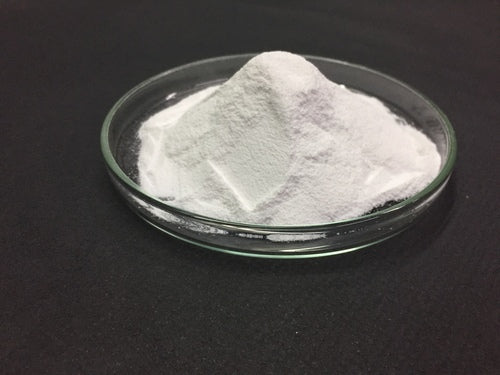

Propylparaben (also known as propyl p-hydroxybenzoate) is a synthetic paraben used as an antimicrobial preservative in various products, including foods, cosmetics, and pharmaceuticals. It inhibits mold and yeast growth, extending shelf life. Regulatory scrutiny has increased due to concerns about endocrine disruption.

The European Commission (EC) banned propylparaben in leave-on cosmetic products intended for children under three years (Regulation (EU) 1004/2014) and restricted its maximum concentration to 0.14% (as acid) in cosmetic products. The U.S. FDA permits its use as a food additive (21 CFR §184.1670) but requires compliance with GMP.

Consumer demand for paraben-free, clean-label formulations is accelerating the shift toward safer, naturally derived preservatives.

Why Replace Propylparaben

- Health & Regulatory Concerns: Evidence of estrogenic activity in animal studies has led to precautionary restrictions, particularly in cosmetics for infants and children.

- Market Trends: The growing consumer avoidance of parabens, particularly in personal care, favors the use of natural and plant-derived preservatives.

- Functional Rationale: Alternatives must deliver broad-spectrum antimicrobial activity, remain stable across a pH range of 4–8, and resist hydrolysis/oxidation while ensuring compatibility with emulsions and active ingredients.

Regulatory Landscape for Propylparaben

| Region / Authority | Current Status | Key Restrictions | Implication for R&D |

| European Union (EC) | Restricted | – Banned in leave-on cosmetics for children <3 years (Reg. EU 1004/2014).- Max concentration: 0.14% (as acid) in other cosmetics. | R&D must avoid using infant products and reformulate to comply with EU regulations. |

| United States (FDA) | Permitted | – Allowed as food additive (21 CFR §184.1670).- Cosmetic use permitted under GMP standards. | Still legally usable, but consumer avoidance makes parabens unattractive in new launches. |

| China (NMPA) | Case-by-case | – Requires safety assessment for cosmetics.- Often aligns with the EU’s restrictive approach. | R&D teams must submit dossiers for approval; the safest path is paraben-free formulations. |

| Japan (MHLW) | Restricted | – Allowed in cosmetics, but restrictions in infant care products.- Must be declared on the label above set thresholds. | Compliance is possible, but consumer perception is strongly negative. |

| Brazil (ANVISA) | Restricted | – Aligns closely with EU precautionary measures. | R&D should follow EU-style limits to ensure approval. |

| Other LATAM (e.g., Mexico, Argentina) | Mixed | – Regulations vary; generally shifting toward EU-alignment. | Paraben-free strategies preferred for regional consistency. |

Manufacturers of Alternatives

1. Symrise AG (Germany)

Symrise offers SymGuard® CD (caprylyl glycol + phenylpropanol) as a multifunctional preservative system. It provides antimicrobial efficacy against bacteria and fungi in pH 4–8 systems. It is a liquid, water-dispersible, and stable up to 80 °C upon heating.

The ingredient is listed in the EU CosIng database and is compliant with the REACH regulation. Symrise provides global regulatory dossiers and formulation support.

2. Ashland Global (USA)

Ashland supplies Optiphen™ series (phenoxyethanol + caprylyl glycol blends) positioned as paraben-free preservatives for cosmetics and topical pharmaceuticals. Optiphen™ products are effective at concentrations of 0.5–1.5%, are compatible with emulsions and surfactant systems, and remain stable across a pH range of 4–8.

They are compliant with EU cosmetics regulations, FDA cosmetic safety guidelines, and supported by global safety assessments.

3 Clariant AG (Switzerland)

Clariant’s Nipaguard SCE is a synergistic blend of sorbitan caprylate, propanediol, and benzoic acid, marketed as a natural preservative system for the personal care industry.

It provides antimicrobial protection at 0.5–1.0% and maintains stability across a wide pH range. The formulation is ECOCERT and COSMOS approved for natural cosmetics. Clariant offers global supply capability and technical R&D collaboration.

4. Schülke & Mayr GmbH (Germany)

Schülke markets euxyl® K 903 (benzoic acid + sorbic acid + benzyl alcohol) as a broad-spectrum, paraben-free preservative blend.

Effective in formulations with a pH ≤ 5.5, it is suitable for natural and organic cosmetics. euxyl® K 903 is approved under the EU Cosmetics Regulation and REACH registered. Schülke offers microbiological challenge testing and customized preservation strategies to support R&D teams.

5. Lonza (now Arxada, Switzerland)

Arxada’s Geogard line (gluconolactone and sodium benzoate, or benzyl alcohol, salicylic acid, and glycerin) is a natural, broad-spectrum preservative blend. They are effective at 0.5–1.0%, stable up to 75 °C, and pH-dependent (optimal ≤ 6.5).

Geogard® products are ECOCERT/COSMOS certified and compliant with FDA and EU cosmetic standards. Widely adopted in skin care, hair care, and topical pharma formulations.

Formulation Considerations

1. pH Compatibility: Many natural preservative systems (benzoic/sorbic acid-based) require pH ≤ 5.5 for optimal activity, unlike parabens, which are broader. Adjustments with buffers may be necessary.

2. Solubility: Alcohol-based blends improve dispersibility; otherwise, solubilizers may be required.

3. Dosage: Typical usage levels are 0.3–1.5%, depending on microbial challenge and formulation matrix.

4. Shelf Life: Preservative efficacy should be confirmed via PET (Preservative Efficacy Testing) under ICH stability conditions.

5. Packaging: Airless dispensers and barrier packaging can reduce preservative load requirements.

Decision Matrix for Preservative Selection

| Factor | Options | R&D Impact |

| Formulation Type | Emulsion, surfactant, aqueous gel | Determines solubility & preservative system |

| pH | Neutral (6–7), acidic (≤ 5.5) | Defines the suitability of organic acid systems |

| Consumer Claims | Natural, ECOCERT, COSMOS | Restricts eligible preservatives |

| Packaging | Jar, tube, airless pump | Alters preservative load requirements |

| Region | EU, US, China, Japan, Brazil | Regulatory compliance varies |

| Cost Target | Premium vs mass-market | Influences concentration, supplier choice |

Conclusion

Regulatory restrictions and consumer preferences are driving the phase-out of propylparaben in multiple applications. Viable alternatives include blends of phenoxyethanol, organic acids, and multifunctional glycols, supported by suppliers with global regulatory documentation.

While replacements may require formulation adjustments (notably pH optimization), they align with clean-label and natural cosmetic trends.

Want to know the best preservative alternatives for your formulations? Submit your requirements through the form below to receive detailed specifications, formulation guidance, and regional compliance.